I love fishing at a 360 degrees. I like to catch fish with lures but also I enjoy modifying lures, tie flies and build rods from time to time. I did build 6 rods in total and even though they are not the state of the art rods I am still very proud of them and I fish with them all the time.

My first rod was a 3 piece custom travel rod. I used a baston blank, fuji alconite guides, seat and eva grips. I did some messy job with the wrapping and epoxy but in the end I ended up with a very functional rod that I still use from time to time. There is nothing more rewarding that catching a fish with a lure you made and a rod you built at home.

If you are interested in rod building or you want to learn more about it you can check the very good videos made by the guys at Mudhole. Mudhole is a US based company that sells rod building equipment and I can say that they are one of the best available online.

You can find more videos here : MUDHOLE YOUTUBE

Another video here:

A Japanese one here about wrap coating:

Showing posts with label DIY. Show all posts

Showing posts with label DIY. Show all posts

October 10, 2013

September 20, 2013

Do Your Own Mini Jig Heads with 3D Eyes

When I saw this video I remembered by old (quite recent) days doing fly tying. I usually buy my small jigheads for LRF and don't spend time making them with hooks and gluing BB weights. This approach with the 3D eyes however is very interesting and quite tempting. I might get some and try soon.

If you like doing some of your lure by yourself you might enjoy this short video.

If you like doing some of your lure by yourself you might enjoy this short video.

Labels:

DIY

August 28, 2013

To Coat Or Not To CoaT

You get a new shiny jig form the store and after a couple of cast you end up with a colorful jig all dented and scratched. This is a serious cause of frustration that I am sure happened to most of us.

A dented and scratched jig keep catching fishes but as fanatics of lures we feel deeply sorry for the beauty of the lure that diminishes after each cast. Fortunately there are some methods that will keep your lure in better shape for a little longer time.

I have seen many videos and articles on magazines about coating the jigs in order to preserve the original state of the jig. Does it work? Is it worth doing it? Expensive? Time consuming? Many question arises regarding this subject.

As far as I know there are two coating agents that are used today by anglers worldwide. One is a single layer of two components epoxy and the other is the single component urethane coating.

Does it work?

Well, in my experience it does work but it all depends on how you apply it and how often you do it. In other words, you can coat the lure and make it resistant but don't expect a seal coat that will make your jig invincible or "immortal". In a way or the other those hard bottom rocks are going to scratch it.

Here is the trick:

You can get a two component epoxy mostly used for hobbies and rod building. First you clean the jig, apply a 800/1000 grit wet sandpaper, you clean with alcohol/thinner and go with the epoxy. You let it dry and it is good to go. Usually one coat is mostly sufficient but it depends also on the thickness of the epoxy used.

The drawback?

Well, with the two part epoxy you need to apply it on several jigs otherwise you will endup with 250cc of epoxy unused and cured at the point that is useless. The best thing to do is to get everything ready, have a nice deep jar in hand and start dipping the jigs.

The other material used is much easier and on the long run cheaper. Some companies sell urethane mono component epoxy. It cures with moisture/air so it has a long working time and it is a quicker and cleaner job.

The drawback?

Even if it virtually doesn't suppose to cure you have to be careful in storing the stuff as the air will in a way or the other start curing the liquid. Secondly, the material , is not as durable as the 2 part epoxy therefore you might need to use it more often.

To summarize:

2 Part epoxy:

+ Durable

+ Widely Available

- Usability

- Needs mixing

Urethane

+ Easy to use. You open the jar and dip it

- Durability

- Needs to be stored properly

- Availability

These are my opinions. Feel free to comment and share your experiences.

A friend of mine has also recommended some floor polish as a good alternative. Need to try and verify it.

Here is a video made by TOHO, a Japanese brand that makes urethane stuff for jigs and lures.

A dented and scratched jig keep catching fishes but as fanatics of lures we feel deeply sorry for the beauty of the lure that diminishes after each cast. Fortunately there are some methods that will keep your lure in better shape for a little longer time.

I have seen many videos and articles on magazines about coating the jigs in order to preserve the original state of the jig. Does it work? Is it worth doing it? Expensive? Time consuming? Many question arises regarding this subject.

As far as I know there are two coating agents that are used today by anglers worldwide. One is a single layer of two components epoxy and the other is the single component urethane coating.

Does it work?

Well, in my experience it does work but it all depends on how you apply it and how often you do it. In other words, you can coat the lure and make it resistant but don't expect a seal coat that will make your jig invincible or "immortal". In a way or the other those hard bottom rocks are going to scratch it.

Here is the trick:

You can get a two component epoxy mostly used for hobbies and rod building. First you clean the jig, apply a 800/1000 grit wet sandpaper, you clean with alcohol/thinner and go with the epoxy. You let it dry and it is good to go. Usually one coat is mostly sufficient but it depends also on the thickness of the epoxy used.

The drawback?

Well, with the two part epoxy you need to apply it on several jigs otherwise you will endup with 250cc of epoxy unused and cured at the point that is useless. The best thing to do is to get everything ready, have a nice deep jar in hand and start dipping the jigs.

The other material used is much easier and on the long run cheaper. Some companies sell urethane mono component epoxy. It cures with moisture/air so it has a long working time and it is a quicker and cleaner job.

The drawback?

Even if it virtually doesn't suppose to cure you have to be careful in storing the stuff as the air will in a way or the other start curing the liquid. Secondly, the material , is not as durable as the 2 part epoxy therefore you might need to use it more often.

To summarize:

2 Part epoxy:

+ Durable

+ Widely Available

- Usability

- Needs mixing

Urethane

+ Easy to use. You open the jar and dip it

- Durability

- Needs to be stored properly

- Availability

These are my opinions. Feel free to comment and share your experiences.

A friend of mine has also recommended some floor polish as a good alternative. Need to try and verify it.

Here is a video made by TOHO, a Japanese brand that makes urethane stuff for jigs and lures.

August 25, 2013

How to Video: Assist Hooks (Twin)

There are many videos out there on how to make assist hooks by yourself. This one is pretty self explanatory. The twin assist hook is very popular nowadays. To tell you the truth I am more inclined to use single assist hooks but I will definitely give a try to the twins.

Check the video:

Check the video:

October 29, 2012

How to make assist hooks (The Video)

In the past I posted an article on how to make assist hooks. Today I am sharing a video I found on youtube. It is very easy to do and the video is well made.

December 25, 2011

DIY: How to make ultra light assist hooks

I like dealing with small sized jigs, hooks, softbaits and everything that is ultralight. Months ago I found a jig that featured a small micro sized assist hook made the same way as the bigger ones used on 60-100g. jigs.

The principle is the same. The assist hook goes to the top or bottom of the jig and allows a secure hook up to the fish.

I am interested in tying flies as well so I realized that I should get some fun by tying this small assist hooks for fun. The materials are quite easy to obtain. A wide gap small sized hook (iseama or chinu type are good for me) , some 50lb PE line as assist line, fly tying thread, crazy glue and some flash.

The result is a nice looking micro assist hook. Below is a quick explanation step by step.

Enjoy :)

|

| I use a small size 8 or 6 wide gap hook. Iseama - Chinu models are fine. |

|

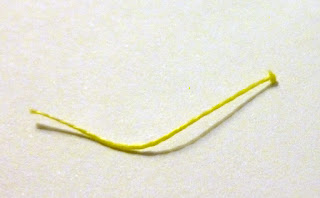

| For the assist line you can use a 30ln or 50lb braid PE line. |

|

| Red colored thread and bobbin. |

|

| Cut the PE at the desired length. |

|

| Make a loop and place it on the shank of the hook. |

|

| Start wrapping the thread |

|

| Add some flash material. I use Crystal Flash. |

|

| Drop some crazy glue for a finishing and securing the wrap. |

|

| Hook is ready to go. |

|

| You can attach it to a small jig with a split ring or directly to the lure snap. |

Labels:

DIY

November 7, 2011

DIY: How to make a light assist hook

This blog is about lure fishing and shore jigging. Since I like using my shore casting jigs with assist hooks instead of trebles, I thought that a nice "how to" post about making assist hooks would be appropriate for this blog.

Below is a simple guide to make a size 1/0 assist hook for medium sized (50-70gr.) jigs. For hooks up to size 1/0 I like using light cords (80-100lb) and Owner hooks SJF-41. (flat head instead of an eye)

I hope it helps :)

|

| 1. For this assist hook I choose an Owner SJF-41 size 1/0 |

|

| 2. As for assist line a Shout 80lb |

|

| 3. Hook and assist line ready to go. |

|

| 4. We start by splicing the line and taking out the core. |

|

| 5. A splicing tool is needed for the job. |

Subscribe to:

Posts (Atom)